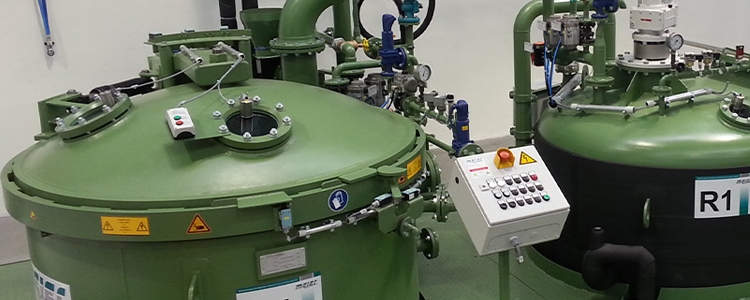

Vacuum Impregnation Process

For many years, porosity has been a major problem in the metal casting process. Porosity in casting can occur as a result of gas bubbles that form as the molten metal solidifies — it can lead to leakage when under pressure, rendering the finished casting virtually unusable. Vacuum impregnation, also known as porous metal sealing or porosity sealing, is a process used to seal porosity in metal castings via the application of vacuum pressure. Vacuum impregnation can be effective in eliminating micro porosity and macro porosity. Micro porosity is confined within the walls of the casting, while macro porosity takes the form of larger cracks or fissures that are visible on the outer walls.

Vacuum impregnation involves the removal of air from the casting that is present during solidification. The void is then filled with a durable material to create a leak-proof seal. When executed properly, vacuum impregnation will seal porosity without changing the structure or appearance of the casting in any discernible way.